Spur Gears

The ‘default’ style of gears, spur gears have simple rectangular teeth around a metal circle.

Helical Gears

The teeth on helical gears are angled diagonally. This makes them ideal for high load systems, as they are generally more quieter and durable than normal spur gears. However, they are also much more difficult to manufacture, and hence more expensive.

Bevel Gears

Used to rotate the plane in which the torque is transmitted, via angled teeth.

Crown Gears

A style of gears where the teeth run parallel to the main gear rather than across the radius. Usually paired with another gear (called a pinion gear). They can transmit torque in perpendicular angles.

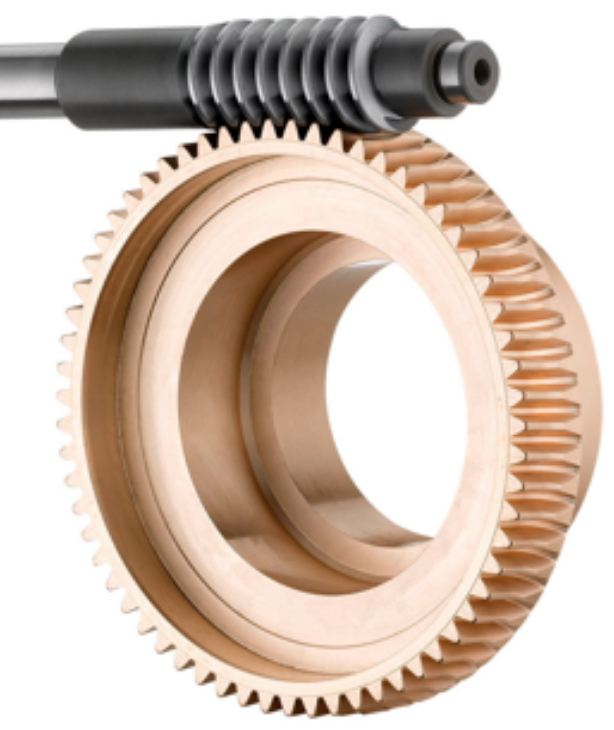

Worm Gears

Long, rod-shaped gears which can compactly transmit torque.Worm gears have the added benefit in that they are always the driver gears i.e. a worm gear cannot be driven.

Internal Gears

When a gear is ‘inside’ another gear, it is said to be an internal gear. These gears are extremely compact, but suffer a key disadvantage, being that the size of the internal gear is limited by it’s parent gear.

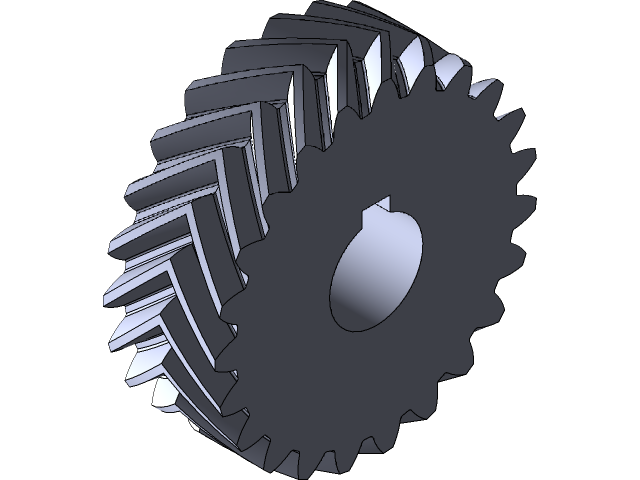

Herringbone Gears (Double Helical Gears)

A variant of helical gears that have V-shaped teeth. They are very quiet and smooth, even at high speeds. However, these are even harder to manufacture.

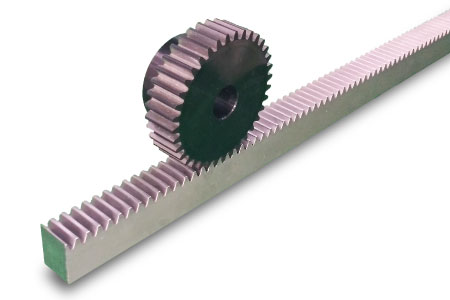

Rack (& Pinion) Gears

A long toothed ‘comb’ which is driven by/drives a spur gear, known as a pinion gear. They convert rotary motion to linear motion.